> Products > Roll Forming Machine > Roofing

Roofing

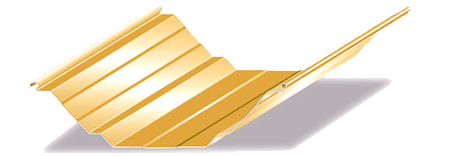

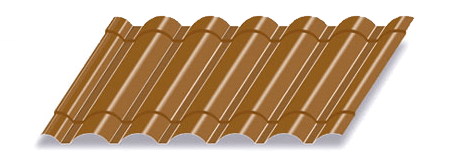

Roofing Sheet

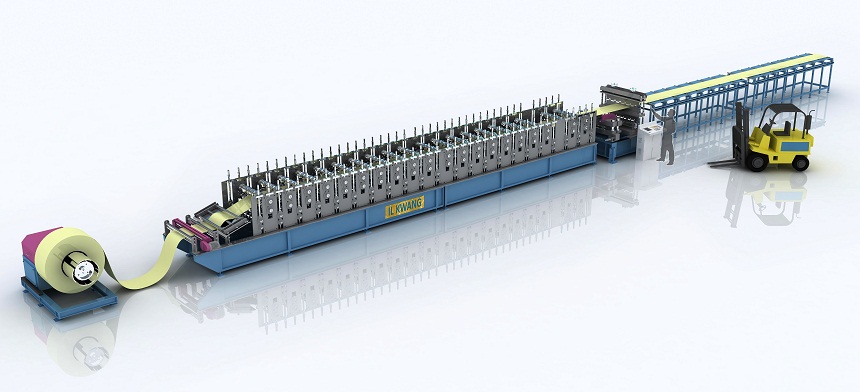

This equipment is manufactured based on the world’s top technology and experiences, and the Roof Panel Producing Line has high durability and convenient management. It enables to manufacture the products of world’s best grade designing various wave forms exquisitely to meet customers’ requirement. In case of applying high speed cutting system of rotary type, products can be manufactured at the high speed of 100m/min or faster.

Un-coiler that inputs and releases coil, Roll Forming Unit that makes shape of coil, and Shearing Unit that cuts the fabricated roof panel, Auto Stacking Unit is a device that loads the completed roofing sheets after cutting properly, and it can discharge products in various ways after loading.

Un-Coiler

Un-coiler is a device that inputs steel coil to feed it stably to the equipment.

Roll forming unit

It is a device that continuously gives shape to sandwich panel as steel coil fed from Un-coiler is engaged between the upper and lower sections of a metal roller.

Shearing & Drawing unit

It precisely cuts and discharges the completed roof panel products. By required speed, GO&STOP shear, Fly type shear, Rotary type shear can be applied and especially the Rotary type shear can be manufactured at the high speed of 100m/min or faster.

Auto stacking unit

Auto Stacking Unit is a device that loads the completed roof sheets after cutting properly, and it can discharge products in various ways after loading.

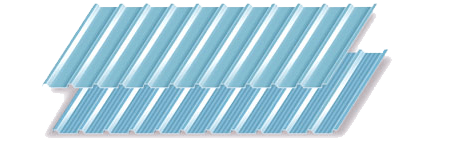

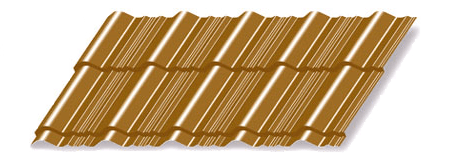

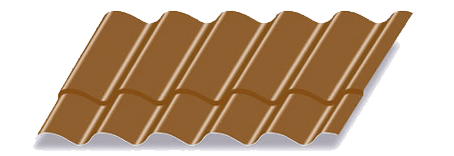

Roofing Tile Sheet

This Roll forming machine for roof tile is a world-class production technology and the experience of a high durability and simply controlled to produce the products. The facility can produce all different and variety designed waveforms based in the best quality.

The Roll forming machine for roof tile, is also can produce a variety of elegant and sophisticated style, metal tile panels and metal shingle tiles, molded panel lines and raised the efficiency of the equipment and to produce normal metal tile roof panels as well as panels.

Un-coiler that inputs and releases coil, Roll Forming Unit that makes shape of coil, and Shearing Unit that cuts the fabricated roof panel, Drawing Unit applying steps to products at the constant depth is adopted. Auto Stacking Unit is a device that loads the completed roof tile sheets after cutting properly, and it can discharge products in various ways after loading.

Un-Coiler

Un-coiler is a device that inputs steel coil to feed it stably to the equipment.

Roll forming unit

Changing over from Cassette type which it through the multi stage rolls to produce the graceful beauty of shapes and Double layer type to make various shapes can be formed through the unit.

Shearing & Drawing unit

The unit applies steps at the constant depth to products that forming has been completed, and scratch does not occur on products at drawing as rigidly finished blade material is used.

And a shearing unit, the device to cut fabricated roof panel, cutting precisely the wave form derived from Roll Forming Unit to the required length and discharge. Various ways can be applied, depending on the required output.

Auto stacking unit

A device that packs panels loaded at Auto Stacking Unit with plastic wrap and discharges them.

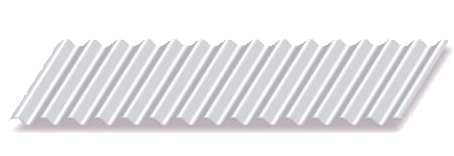

Profiles: Roll forming machine for Roofing

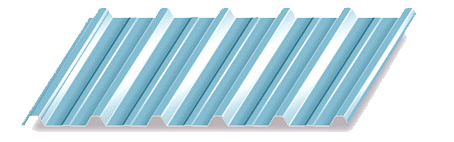

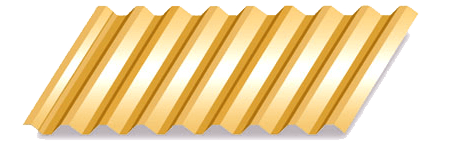

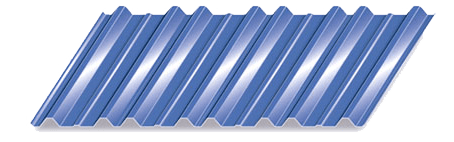

IKS-SR200

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 1000mm

- Pitch : 200mm

- Depth : 24mm

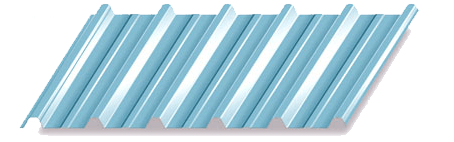

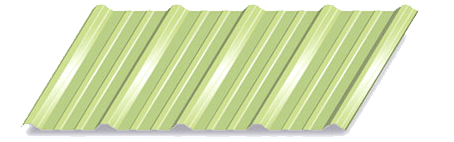

IKS-SR190

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 950mm

- Pitch : 190mm

- Depth : 30mm

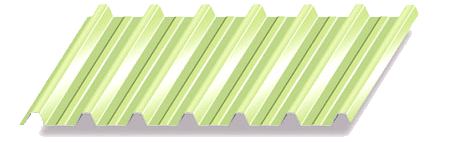

IKS-SR150

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 900mm

- Pitch : 150mm

- Depth : 32mm

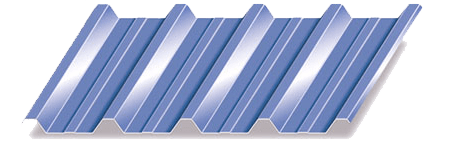

IKS-V115

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 920mm

- Pitch : 115mm

- Depth : 35mm

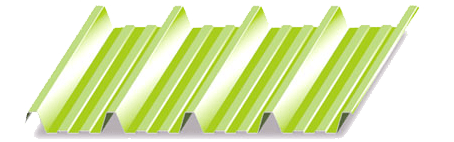

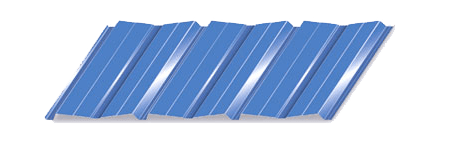

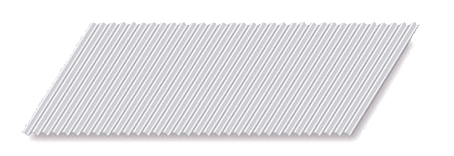

IKS-V250

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 1000mm

- Pitch : 250mm

- Depth : 30mm

IKS-V272

- Coil width : 1250mm

- Coil thickness : 0.4~0.7mm

- Finished width : 1088mm

- Pitch : 272mm

- Depth : 30mm

IKS-RO-P264

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 1056mm

- Pitch : 264mm

- Depth : 24mm

IKS-RO-D250

- Coil width : 1219mm

- Coil thickness : 0.5mm

- Finished width : 1000mm

- Pitch : 250mm

- Depth : 25mm

IKS-RO-P333

- Coil width : 1219mm

- Coil thickness : 0.5mm

- Finished width : 1000mm

- Pitch : 333mm

- Depth : 32mm

IKS-RW-P333

- Coil width : 950mm

- Coil thickness : 0.5mm

- Finished width : 1000mm

- Pitch : 333mm

- Depth : 26mm

IKS-WA-MP98

- Coil width : 1250mm

- Coil thickness : 0.4~0.7mm

- Finished width : 1078mm

- Pitch : 98mm

- Depth : 125mm

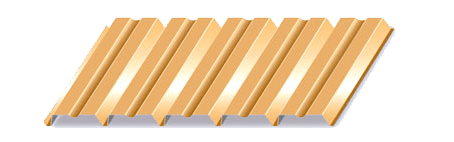

IKS-DK-T40

- Coil width : 1250mm

- Coil thickness : 0.5~0.8mm

- Finished width : 810mm

- Pitch : 162mm

- Depth : 40mm

IKS-W655

- Coil width : 914mm

- Coil thickness : 0.6~1.0mm

- Finished width : 655mm

- Pitch : 655mm

- Depth : 166mm

IKS-C76

- Coil width : 1219mm

- Coil thickness : 0.4~0.7mm

- Finished width : 990mm

- Pitch : 76mm

- Depth : 18mm

IKS-WA-C31

- Coil width : 1250mm

- Coil thickness : 0.4~0.5mm

- Finished width : 986mm

- Pitch : 31mm

- Depth : 9mm

IKS-TI185

- Coil width : 1200/1220mm

- Coil thickness : 0.4~0.7mm

- Finished width : 925mm

- Pitch : 185mm

- Depth : 27mm

IKS-TI167

- Coil width : 1200/1220mm

- Coil thickness : 0.4~0.7mm

- Finished width : 1000mm

- Pitch : 167mm

- Depth : 40mm

IKS-TI200

- Coil width : 1200/1220mm

- Coil thickness : 0.4~.7mm

- Finished width : 1000mm

- Pitch : 200mm

- Depth : 30mm